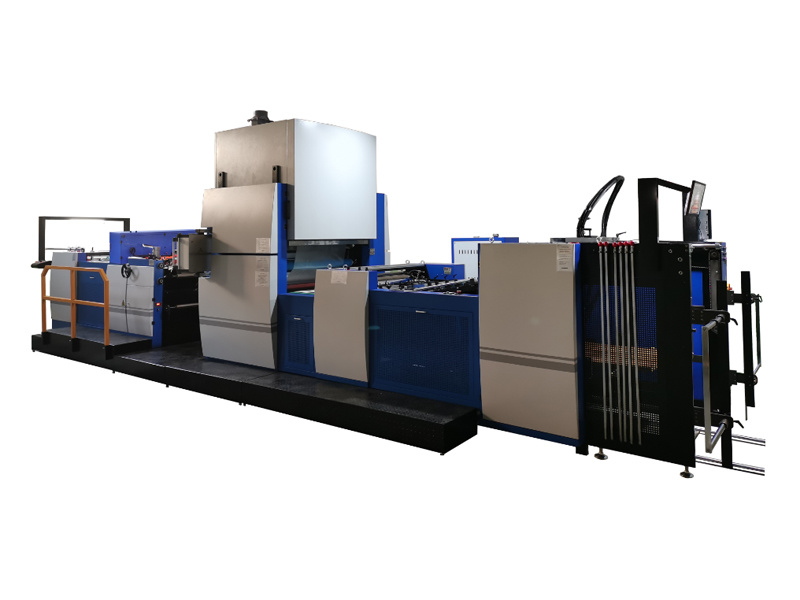

GPM-1040

Highspeeddigitalinkjetprinter

Category:

Disc Knife Laminating Machine

Product Description

it is suitable for sheet fed paper, multi line code print system and inspection by one pass.This platform is suitable for differrent types of water based and UV varnish inkjet systems, and printerheads. Printing a variety of bar code (1D, 2D, etc. ), dynamic and fixed text information, dynamic andfixed bitmap information production by one pass, the machine is widely applied to lottery tickets, ticketsmarket.

The paper feeding platform adopts cast wall structure, shock absorbtion is good, the paper is stable andthe inkjet printing precision is high.

Vacuum area inkjet print platform, use a set of entire suction belt to ensure the high precision of inkjetproducts. Vacuum area enough size to ensure the max, sheet size paper in the vacuum platform tocomplete the code print process.

Water based drying unit,with pre-heating, air knife structure , low energy consumption, high efficiency.and fast drying. Use high temperature mesh belt , easy operation and long service life. Use pressure aircollection system, pneumatic rollers deceleration, to ensure thick or thin paper smooth collection,stacker equipped with waste sheets automatic rejection , to ensure the waste sheets does not stack withthe finished products. Optional: pre-stacker, powder remove , waste sheets rejection, varnish coating.

| Mode | Max.sheet size | Min.sheet size | Max.speed | Weight | Power | Overall dimension |

| GPM-1040 | 1040×740mm | 290×290mm | 160m/min | 4520kg | 25kW | 10×1.2×1.8m |

Keywords:

Highspeeddigitalinkjetprinter

Related Products

Welcome your message consultation

Any questions? Get in touch. We'd love to hear from you.