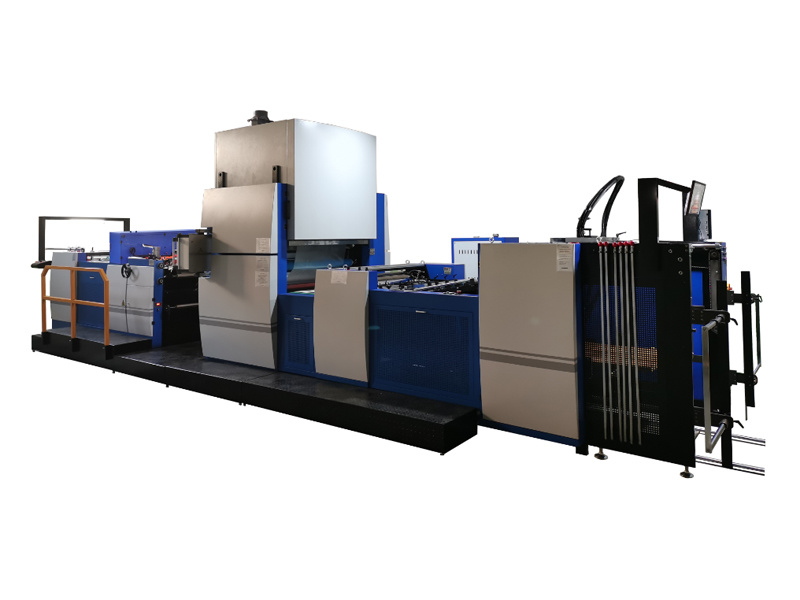

YZFM-1080MG

Fully automatic high-speed thermal laminating machine

Category:

PRODUCTS

Chain Knife Laminating Machine

Product Description

Machine characteristics:

This machine is equipped with pre-stacking paper mechanism,It saves time to shut down the machine;Equipped with front lay and pull lay to ensure the straightness of the lamination products;Servo motor controls the precision of paper lap, ensuring that the paper lap is within + 2mm;The main press roller is heated by the mould temperature machine,Accurate control of temperature, so that the heating roller surface temperature is consistent everywhere;The product adopts punching, pull off film to cutting, and the whole machine's display screen is controlled centrally. The operation is convenient and all data are clear at a glance.

TECHNICAL PARAMETER

| Max.sheet size | 1080*1200mm |

| Min.sheet size | 320*260mm |

| Paper thickness | 105-500g/㎡ |

| Film thickness | 0.01-0.02mm |

| Max.lamination width | 1080mm |

| Max.film roll diameter | 450mm |

| Film type | thermal film film |

| Max.speed | 10-100m/min |

| Total power | 39KW |

| Production of KW | 10-20kw/hour |

| Machine weigh | 5200kg |

| Overall dimensions | 9536*2900*1900mm |

Introduce performance of each part

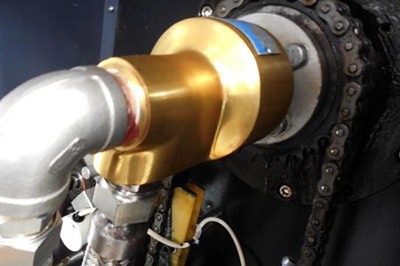

- The key of precoating technology is the control of temperature change,Get the temperature of lamination to ensure the quality of the mulch

In view of the special properties of thermal film, Warwick has conducted in-depth research.The technology of mirror roller made in Germany was introduced and the temperature fluctuation range of precoated film was controlled effectively,The heat conduction oil circulation and the mould temperature machine were adopted to make the temperature difference change in a very small range,No matter your product quality or speed, we can guarantee the constant temperature of the lamination, so as to ensure the quality of the film coating. -

Introduce performance of each part Feeder

-

- 1、High accuracy four-feed four-suction feeder

2、The feeder part is equipped with non-stop feeding, with thin paper flattening mechanism;

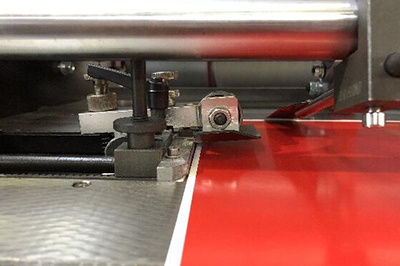

3、Equipped with delicate pull lay and front lay and auxiliary positioning pressure sheet,prevent the paper from warping over the front lay and the former regulation is not in place;

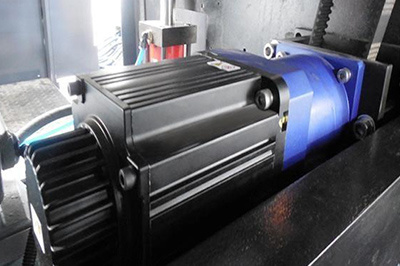

4、Servo motor is used to control the paper lap, even at full speed, the accuracy

reaches±2mm.

Feeding paper speed 12000pics /hour

-

Equipped with pre-stack paper mechanism, with no downtime feed paper functions -

Pull lay mechanism and front lay mechanism to make sure the coated paper is straight linearity, improve the quality of lamination -

Stable and reliable servo motor control The accuracy of lap joint ensures that the lap joint is ±2mm dimensional accuracy

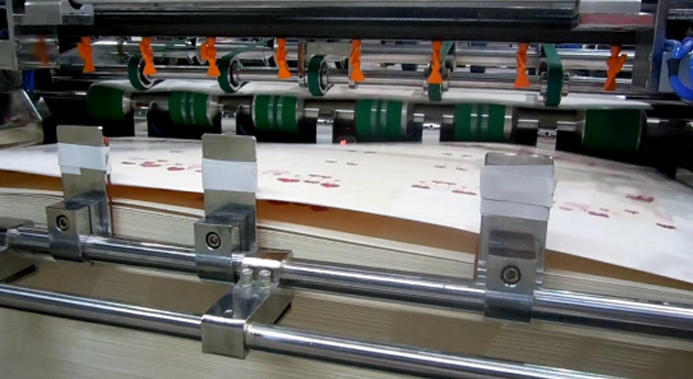

Introduce performance of each part laminating unit

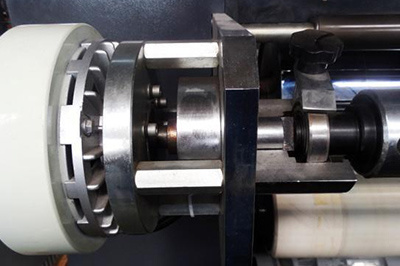

- The inner circulation mechanism of the mirror hot- pressing roller with a diameter of 380mm is covered with film.This is the main key part in the film coating process. It is made through dozens of processing procedures. The precision grade is IT6.The temperature error of roll surface can be controlled within 3 degrees.The temperature change of hot oil in roller can be guaranteed by mould temperature machine and controlled automatically.Due to the small temperature change, the quality of large ink print is also largely avoided.

-

-

-

After lamination products through air-cooled treatment, can reduce the printing products after lamination high temperature resulting in paper deformation -

The press mechanism adopts the automatic boost of hydraulic station 。 The film winding tension is manually adjusted by magnetic powder tension mechanis -

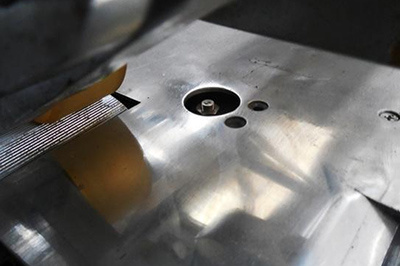

When the film is wider than the print width, the mechanism can be used to cut the excess film

Introduce performance of each part Cutter unit

-

In order to ensure the accuracy of the cutting, before enter the cutting mechanism, the paper sheet after the film-coated first through the paper stretch mechanism,It can effectively avoid the curl of thin paper after film mulching and allow the paper to enter into the cutting completely flat to avoid the waste sheets affecting the work efficiency or causing waste. -

The paper length of the paper drawing part is adjusted automatically, and theclutch pressure is controlled by pneumatic. The new pneumatic cutting mechanism can control the edge of the filmeffectively, and the highest cutting speed can reach 10000 pieces per hour

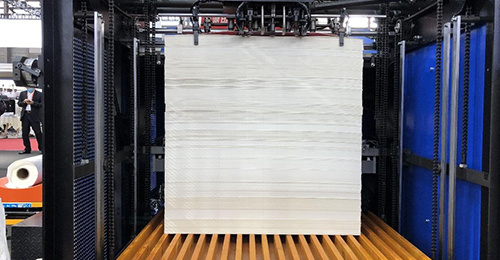

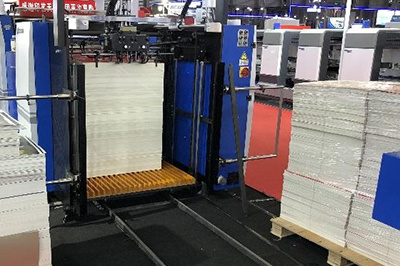

Introduce performance of each part paper stacker

There is a safety stop button for the rising of the paper stacker, and the lifting motor of the paper stacker is equipped with brake to prevent the labor safety hiddendanger of the paper stacker platform falling rapidly.

with air conditioning system.

Two-lay cylinder action sensitive, long service life.

The device is suitable for increasing the hardness of thin paper when the paper is collected quickly.The bottom of the paper is equipped with a supplementary air supply device. Blowing mechanism: under blowing can help thin paper to enter the paper receiving table smoothly, on blowing can effectively reduce the paper temperature.

Keywords:

Related Products

Welcome your message consultation

Any questions? Get in touch. We'd love to hear from you.