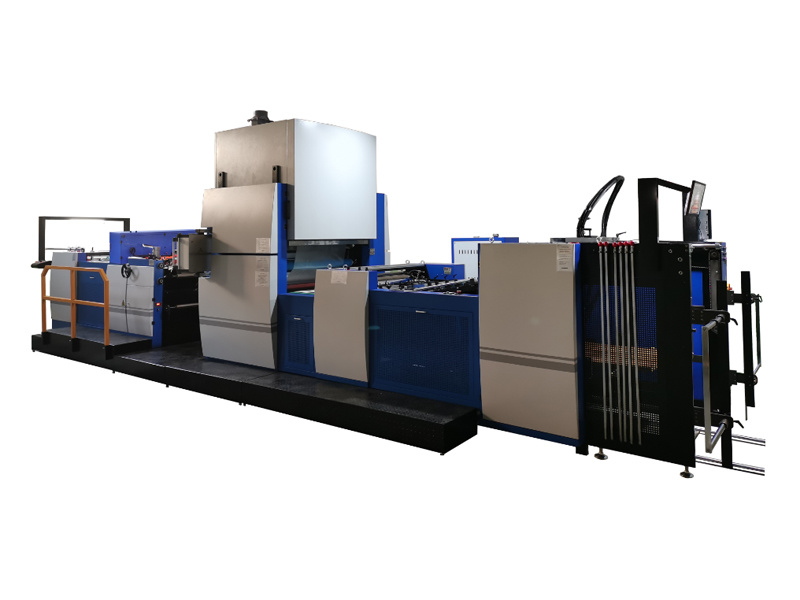

KPZ-1100MC

Fully Automatic Format UV Coating Machine

Main technical parameters

Max.sheet size:1080 x 1200 mm

Min.sheet size:320 x 290 mm

Paper Thickness:80-250g/㎡(need add air knife) 250-600g/㎡

Production Speed:25-80m/min

Total Power:65 kw

Total Weight:7500kg

Overall Dimension:13500 x2000 x 1600mm

Main Configuration:Feeder +Water Powder Cleaner + UV Coating Unit + UV heater + Paper Stacker

Category:

PRODUCTS

UV Coating Machine

Product Description

Main technical parameters:

| Max.Coating Width | 1060mm |

| Max.Paper Size | W1080×L1200mm |

| Min.Paper Size | W320×L350mm |

| Piling Height | 1300mm |

| Paper Thickness Optional Air Knife |

250-600g/m² 80-600g/m² |

| Max.Speed | 100m/min |

| Installation Power | 86kW |

| Total Weight | 8800kg |

| Dimension Size | 22.352×2.7×2.0m |

Configuration

| Name | Brand |

| Vacuum Pump | German Baker |

| Touch screen | Delta 10 inches |

| Relay | Weidmüller,Germany |

| Contactors,Motor protectors | Siemens |

| Circuit breaker,Button | CHINT |

| Solenoid valve | SMC,Japan |

| Bearing | NSK,Japan |

| PLC | Inovance |

| Frequency converter,servo | Inovance |

| limit switch | Yang Ming ,Taiwan |

| Photoelectric switch | Baumer,Swiss |

| Two-piece air valve | STNG,Taiwan |

| cylinder | Airtac,Taiwan |

| encoder | PANHOFF,Germany |

| mesh belt | Teflon mesh belt |

| Belt | Habasit,Swiss |

| chain | Choho,Japan |

| Coating rubber roller | Imported polyurethane material |

| switching power supply | MEAN WELL,Taiwan |

| Oil scraper blade | SND |

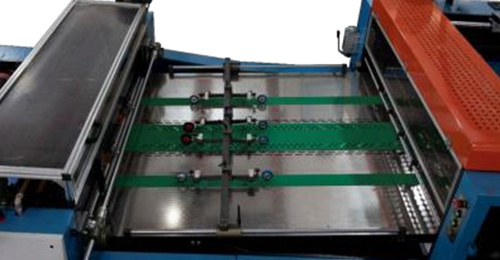

- 1. Automatic paper feeder: The speed of the paper feeder can reach up to 10,000 sheets per hour; the feeder drive of the paper feeder can move forward and backward, making it convenient for the paper feeder to feed large and small size paper; Paper feeder can produce paper size: W1080×L1200mm Four suction and four feeding feeder,

-

-

- The paper feeding table can be raised and lowered manually; the upper and lower limits of the paper feeding table are protected; Double or multiple paper feeding detection and shutdown system; stepless frequency conversion paper feeding; Feeder paper table rising protection device: There are micro switches above the paper table and at the feeder head to prevent the paper from being lifted too high and hitting the feeder head. Feeder platform can be folded. Convenient for daily maintenance.

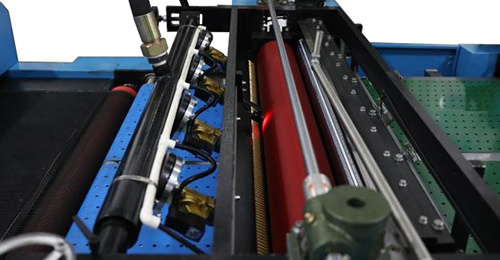

- 2. Coating unit: three-roller coating, coating roller diameter 150mm;paper brake to protect the roller; The bottom roller adopts a reverse scraper. The host wall panel is made of high- quality castings, has long service life, good structural rigidity,and does not vibrate during high-speed operation. Coating roller material: imported material, durable and not easy to deform.

-

-

- 3. IR drying light box: 18 pics 2.2kW IR lamps; The constant temperature IR light box can set the operating temperature according to product requirements, saving power consumption and quickly drying water- based varnish;

4. Cooling fan: three rows of cooling fans.

- 5. Automatic collection plate machine (with auxiliary table): The paper collection is neat, and the auxiliary paper collection platform and automatic paper collection machine can be converted into use. 7.Design concept: A multi-purpose varnishing machine with a high degree of automation, the coating is smooth and delicate, saving varnish and meeting high requirements. 8. Equipment advantages: Complete functions, humanized design, simple operation, high configuration, mainly imported electrical and bearings

-

7.Design concept:

A multi-purpose varnishing machine with a high degree of automation, the coating is smooth and delicate, saving varnish and meeting high requirements.

8. Equipment advantages:

Complete functions, humanized design, simple operation, high configuration, mainly imported electrical and bearings

Keywords:

Related Products

Welcome your message consultation

Any questions? Get in touch. We'd love to hear from you.