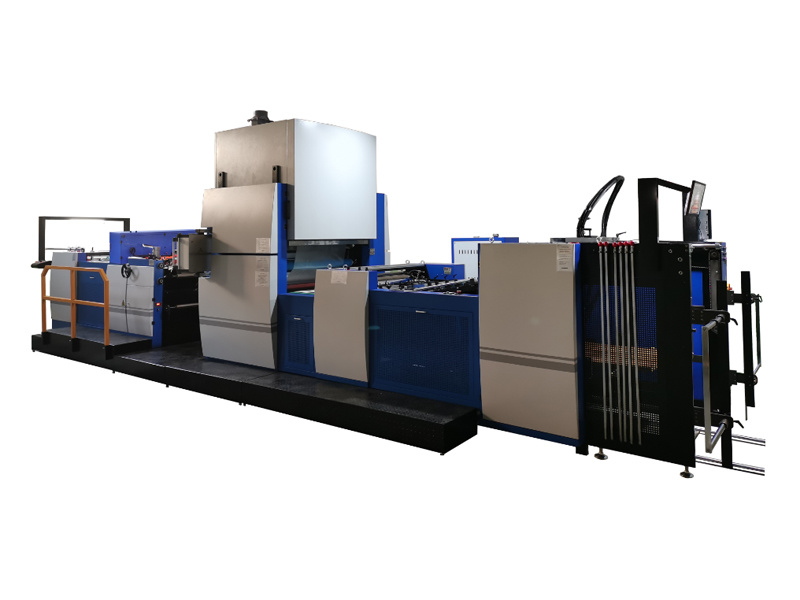

ZFM-1080LCL

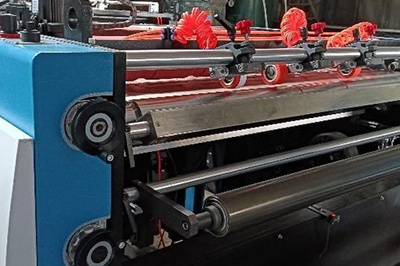

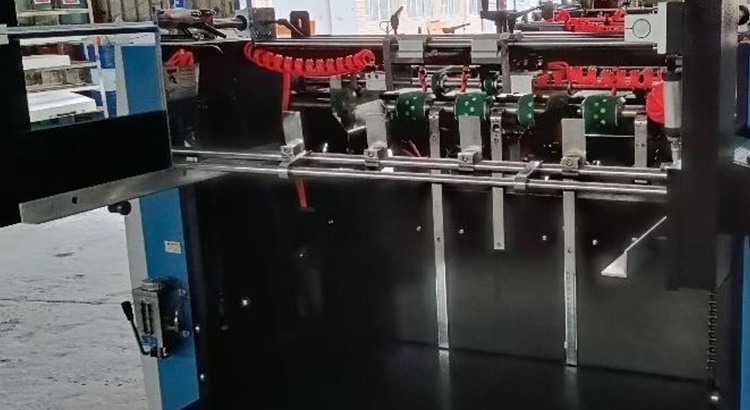

Automatic Chain knife Film Laminating Machine

Category:

PRODUCTS

UV Coating Machine

Product Description

Technical advantages

Special technology:

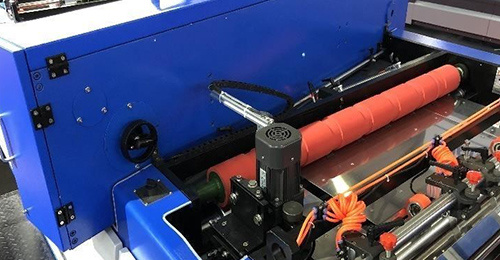

heat transfer oil built-in circulation system The rolling surface has less temperature difference, good constant temperature effect in high-speed operation, saving electric energy, and faster speed on the premise of ensuring the lamination quality

Technical parameters:

| Model | ZFM-1080LCL |

| Max.sheet size | W1080×L1450mm |

| Min.sheet size | W320×L 350mm |

| Suitable sheet thickness | 105-500 gram |

| Feeder pile height | 1300 mm |

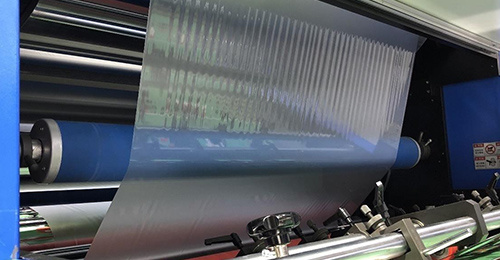

| Film thickness | 0.01-0.02mm |

| Installed power | 81kW (380V AC3φ 50 Hz) |

| Working power | 18-35kW |

| Mechanical speed | Max.100 m/min,or 11000sheets/hour |

| Working speed | 20-100m/min,(according to different paper,different requirements and different specifications) |

| Overall dimensions | L14025×W2900×H3100 mm |

Main Parts

| Main Parts | |

| Miniature Relay | Moeller,Germany |

| Contactor | SIMENS,Germany |

| Botton | Moeller,Germany |

| Encoder | Panhoff,Germany |

| Vacuum Air Pump | Becker,Germany |

| Sensor | Panasonic,Japan/Baumer, Switzerland |

| Bearing | NSK,Japan |

| Machine Chain | CHOHO,Japan |

| Solenoid Valve | SMC,Japen |

| Frequency Converter | Inovance,China |

| Feida Serve Motor | novance,China |

| Servo Driver | Inovance,China |

| PLCControl | Delta,Taiwan |

| Touch Screen | Delta,Taiwan |

| Feida Paper Receiving Brake Motor | Wanshsin,Taiwan |

| Main Motor | Wanshsin,Taiwan |

| Pneumatic Components | AirTAC,Taiwan |

| Conveyor Belt | Habastic,Switzerland |

- The large-diameter hot roller for drying the glue adopts heating tube for constant temperature, the roller surface temperature is balanced, and the film can be dried with hot air. The water- based glue can be solidified quickly to achieve the purpose of high-speed film lamination; The roller surface is chrome plated and polished, with long service life and easy cleaning;

-

-

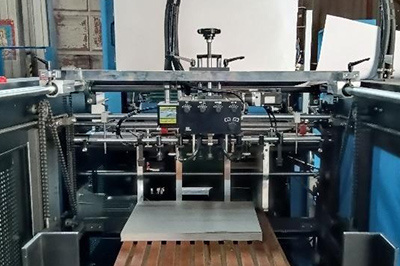

- Technical advantages: Special technology: heat transfer oil built-in circulation system The temperature of the mirror heating roller with a diameter of 380mm is constant by mold temperature machine; There is a heat transfer oil circulation mechanism inside the roller; The larger the roller diameter, the more average the temperature, the better the heat constant temperature effect, and the longer the lamination hot pressing time, the better the lamination effect. Sheets Cutting method: Chain knife cutting system

Configuration:

-

Non-stop Feeder -

Mold temperature controller -

Thin paper anti curling

-

Front lay, Sheets drawing -

Powder remove unit

-

Fly-cutter unit -

Non-stop Stacker

Optional :

-

Hot knife cutting system -

Double lamination,Embossing unit -

UV enhancement unit

Keywords:

Related Products

Welcome your message consultation

Any questions? Get in touch. We'd love to hear from you.